- Supply quality multifunctional grain cleaner

- Provide the detail information of maize huller

- Professional knowledge of maize milling machine

- Welcome to consult our maize grinding machine

- Share our advanced technology & machinery on canton fair

- Guangzhou Canton Fair 2013 October

- 1

- 2

- 3

- 4

- 5

- 6

What You Want to Know about Maize Dry Milling Process

Maize milling is a universal way to add the extra value of maize. Maize meal and grits are not only available for human consumption and livestock feed but a component of making ethanol, sugar, beer, maize starch and others. There are two main way of maize milling: wet milling and dry milling, which is mainly used in industry alcohol process. After mill, you will get maize grits, maize meal, maize starch and maize germ, which are necessary in making food, and ethonal. Today, the primary information of maize dry milling process will be provided by KMEC.

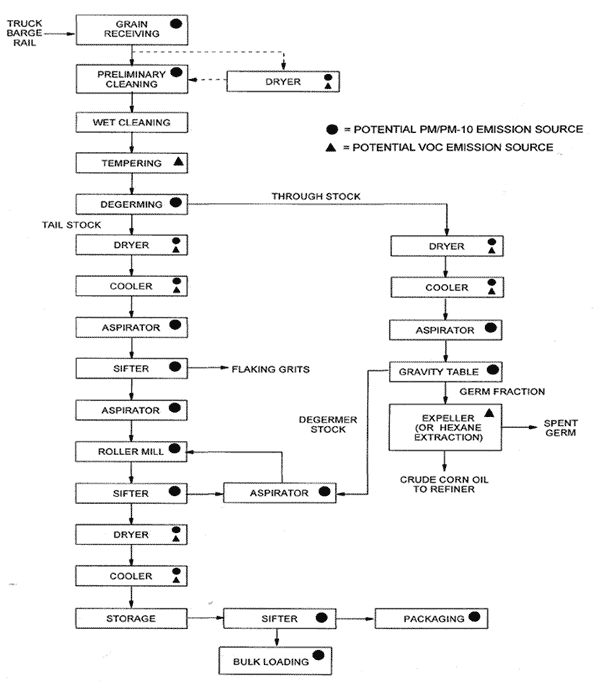

Degerming Process

Maize kernel consists of endosperm, germ, cortex and calyptra. Basic process of maize mill includes cleaning, de-stoning, peeling, then degerming, milling and the final step, separating different products. In degerming process, what you need to do first is dry clean the maize and separated broken maize from the entire one and removes foreign material and dirt, dust. During the wet clean process, the majority of dust, bran, germ and so on will be removed and left endosperm. After cleaning, maize should be kept 20% moisture. Then, smaller grits, meals are produced by utilizing roller mill, grinding and aspirating machine.

Processing Machine

During maize dry milling process, majority machine you can use is maize cleaning machine, degerming equipment, maize milling machine and grits making equipments. KMEC is ready to provide you the professional information and an array of high efficient maize processing machine.

Added Value

6-8% added value and net profit can be reached after maize dry milling process.

you're interested in our products

or

have any questions about it,

please let us know.

Don't hesitate to contact us!